How can PLM systems effectively aid returns management/reverse logistics?

My views on the topic at MCADCafe Blog: http://www10.mcadcafe.com/blogs/plm/2012/05/13/effective-product-returns-using-plm/

Showing posts with label PLM. Show all posts

Showing posts with label PLM. Show all posts

Monday, May 14, 2012

Effective Product Returns using PLM

Labels:

PLM,

Product Returns,

Returns Management,

Reverse Logistics

Friday, April 27, 2012

My PLM blog crosses the 10,000 page views mark…

Yeah I know a lot of sites have 10,000 visitors every day (probably

before even I begin my day), so my blog crossing the 10,000 Page views mark (in

fact its 11000+ views now) over the course of two years might not be a big occasion

for some. But anytime the page view stat crosses a certain order of scale you

have to celebrate it some way – especially when you are a hobbyist/weekend

blogger and write on a very niche topic.

I usually

do not check the stats – and when I did today I was delightfully surprised. So –

I want to appreciate my readers from around the world for perusing the posts

and recommending the articles for others to read. Thank you so much!

As usual please feel free to leave comments if you like. I

look forward to hearing from more of you.

Labels:

PLM

Saturday, April 7, 2012

Cloud Based PLM and Enterprise Application Integration

Putting PLM in the cloud is not enough – What matters most is enterprise application integration.

Putting PLM in the cloud is not enough – What matters most is enterprise application integration.Read my thoughts on this topic at MCADCafe: http://www10.mcadcafe.com/blogs/plm/2012/04/03/cloud-based-plm-and-enterprise-application-integration/

Friday, April 6, 2012

Increasing Software in Automobiles – Can ALM-PLM Help?

My thoughts on increasing amount of software in today's automobiles and how a ALM-PLM solution can help.

Read more at MCADCafe: http://www10.mcadcafe.com/blogs/plm/2012/03/06/increasing-software-in-automobiles-can-alm-plm-help/

Read more at MCADCafe: http://www10.mcadcafe.com/blogs/plm/2012/03/06/increasing-software-in-automobiles-can-alm-plm-help/

Thursday, March 22, 2012

Competing on Analytics – Time for PLM based Analytics?

In my opinion PLM vendors currently provide fragmented analytics

tools – Most of them address only a very specific section of the

addressable market need. Also the problem seems to be compounded by the

fact that not only companies implement a closed-loop PLM system thereby

making data collection much tougher. PLM vendors should start taking

note of the emerging trends (specially the “big data” problem) and start

providing value-added analytics products to customers.

Monday, January 16, 2012

Holiday Spending, Returns and Need for a Closed Loop PLM System

I was reading about the 2011 U.S. Christmas Holiday Retail

Data this weekend and noted some interesting points:

- According to the National Retail Federation, December retail industry sales (which exclude automobiles, gas stations, and restaurants) increased 4.1 percent to $471.5 billion – slightly surpassing NRF’s holiday sales forecast of 3.8 percent growth. [source]

- Gifts are the most common purchase that consumers make during the major holidays (nearly 50%). Top gifts categories were: Clothes, Gift cards, Electronics, Jewelry, Home and garden, Personal care, cosmetics and pampering, Toys, sporting goods and hobbies.

- Shoppers are expected to return 9.9% of their Christmas purchases, which would be the highest return rate since the recession. [source]

- $46 billion of merchandise is predicted to be returned, which would be a 4% increase when compared to holiday gift returns in 2010. About 33% of shoppers said they return gifts in the NRF 2011 Holiday Returns Survey. [source]

- Reasons for returns vary: Buyer’s remorse, better deals elsewhere, unwanted gifts, too many of certain kind, shopping error etc. [various sources]

One of the major reasons for return also is because of manufacturing

defects. Usually all merchandise with manufacturing defects that are returned

by customers are claimed back to the producer by retail vendors, even if this

occurs after the “selling season”. Although I couldn’t get any specific data on

the amount of returns due to faulty products but I assume it will be a

significant amount in dollar terms.

Managing product returns due to manufacturing defects, obsolete

products and shipping errors is difficult to say the least. Manufacturers must manage

the reverse flow efficiently to ensure maximum recovery, and reduced wastage. While

larger manufactures due to deeper pockets might be able to withstand the

financial effects of high returns, smaller manufacturers tend to lose a lot

more.

Hence it is imperative that they:

- Integrate their Quality Lifecycle Management (QLM) and Reliability Management solutions with their PLM solution. This will not only trim down the cost of poor quality but also will allow them to utilize lessons learned to augment product designs (thereby closing the loop in the product lifecycle).

- Integrate Warranty Management into PLM so that manufactures can build an early-warning closed-loop system which will enable continuous product and service improvement.

- Develop strategies for End-Of-Life Management so that returned products can be refurbished, repaired or disposed efficiently and in a cost-effective manner. For high-value, high-velocity products it makes sense to integrate the Returns Management platform with PLM for better asset recovery, warranty, returns, repair, and refurbishing, packaging and repackaging services.

My 2 cents – Would like to hear your thoughts on this.

Tuesday, November 8, 2011

Adobe’s Solutions for Manufacturing

Adobe Systems

has historically focused upon creating multimedia and creativity software

products, with a more-recent foray towards rich Internet application software

development [http://en.wikipedia.org/wiki/Adobe_software]. With ubiquitous

products like Adobe Photoshop, InDesign, Illustrator, Fireworks, Acrobat, Flash

etc I was surprised to see Adobe's offerings for the manufacturing world.

(Maybe it’s there for some and maybe I have just noticed while writing my

previous blog post “3D PDF Technology – Where it fits in”).

"Adobe and

partner software can be used to publish, protect, review, and archive product

data as part of these and other product lifecycle management (PLM) workflows:

3D model-based definition (3D MBD), Item master creation, First article

inspection (FAI) reports, Engineering change orders (ECOs), RFPs/RFQs

etc." [http://www.adobe.com/manufacturing/solutions/product_development/]

This image

shows where Adobe is trying to push its product in the PLM world:

I am not sure how successful Adobe has been in its endeavor to optimize product development since they are so much PLM vendor dependent to tie up with actual PLM systems. However I do think Adobe will be successful in helping organizations create and deliver more effective technical communications and enhance customer service because of their history. From their site: "Leverage 2D and 3D engineering data in the creation of technical publications (Work instructions, Field service manuals, Training manuals etc) for manufacturing, assembly, sales, service, and support. Provide technical publication users with a much richer, easier to understand learning experience by sharing 3D data in a more secure, easy-to-use format — 3D PDF. Whether it's a local field service technician repairing a commercial pump or military personnel in a remote desert outpost maintaining an F/A-18, anyone, anywhere can view rich, interactive 3D manuals electronically with free Adobe® Reader® software, which is installed on over 90% of Internet-connected PCs." [http://www.adobe.com/manufacturing/solutions/work_instructions/]

Monday, November 7, 2011

3D PDF Technology – Where it fits in

I happened to read about PROSTEP PDF Generator 3D in CIMData’s website this weekend

which lead me to explore the world of 3D PDF’s. I find interactive 3D PDF files pretty amazing. For those of you

who haven’t had a chance to view them please click on this link: http://www.adobe.com/manufacturing/3dpdfsamples/3dsolutions/

to view sample 3D PDF files. There are several examples listed like:

I happened to read about PROSTEP PDF Generator 3D in CIMData’s website this weekend

which lead me to explore the world of 3D PDF’s. I find interactive 3D PDF files pretty amazing. For those of you

who haven’t had a chance to view them please click on this link: http://www.adobe.com/manufacturing/3dpdfsamples/3dsolutions/

to view sample 3D PDF files. There are several examples listed like:

→ Turbine engine (PDF, 4.5M, Original CAD format:

SolidWorks)

→ Jet concept design (PDF, 4.7M, Original CAD formats:

Siemens NX, CATIA V5, and Pro/ENGINEER Wildfire)

→ Crankshaftassembly (PDF, 3.0M, Original CAD format: Pro/ENGINEER Wildfire)

I observed many tools when I opened

these files in Adobe Reader including those to isolate Parts, different Part

Rendering Modes including Transparent, Wireframes, Illustrations etc, different

Model Rendering Modes, Model Tree highlighting - will highlight different parts

in the model, 3D measurement tools, etc. PDF Generator 3D Reader Extensions Module offers the option of activating a large number of additional functions for using the generated 3D PDF documents in Adobe Reader. The recipient can, for example, add comments or fill in certain fields on a form. PDF Generator 3D Rights Management Module allows the information contained in the 3D PDF documents to be protected against access by unauthorized persons. Access rights can be restricted to a specific period of time and if necessary can be revoked when, for example, a document is no longer valid. Overall I feel it’s a good tool for

visualization even though rendering and loading takes some time even with a

powerful computer. For those interested in the details of the components of PDF Generator 3D have a look here:

I see 3 major advantages of using 3D

PDF technology:

→ Standardization: No doubt

there are visualization tools from nearly every CAD vendors which will help view

a multitude of product data (e.g., MCAD/ECAD files, MS Office documents)

without the authoring application. But all such tools need the downstream

consumers to have the same tools which might be difficult considering that

manufacturing and support services are likely to be outsourced. I think Adobe tries to solve this problem

with Interactive 3D PDF. “Interactive 3D PDF files look exactly like the

original 3D design, regardless of the application used to create it or the

environment in which it's viewed.” [http://www.adobe.com/manufacturing/solutions/3d_solutions/] The currently supported CAD formats are:

→ Reduction in Total Cost of Ownership: If your

product data needs to be viewed across the Realise (Manufacturing), Use/Support

(Customer service), Retire/Dispose phases (The phases are from John Stark's PLM

Grid) then each user associated with the individual phases will need licenses

for a visualization tool. With 3D PDF that cost is cut down. Since Adobe

Acrobat is installed in the majority of users – this would also mean a reduced load

on IT for installing and maintaining the visualization tool. However a details

cost benefit analysis should be made comparing the total license costs of the

currently used desktop-based visualization tool versus the cost of the 3D PDF

Generator tool (a professional server solution that offers full functionality and accommodates up to 50 users for less than € 10,000).

→ Long Term Archival and Retrieval Solution: If the

lifecycle of your product extends several decades then a question worth

pondering is whether the CAD format would still be supported. While the PDF specification was available for free since

at least 2001, PDF was originally a proprietary format controlled by Adobe, and was

officially released as an open standard on July 1, 2008, and published by the International

Organization for Standardization as ISO 32000-1:2008.

In 2008, Adobe published a Public Patent License to ISO 32000-1 granting a

royalty-free rights for all patents owned by Adobe that are necessary to make,

use, sell and distribute PDF compliant implementations. [http://en.wikipedia.org/wiki/Portable_Document_Format].3D

PDF is the perfect candidate for a long term archival and retrieval solution. More

information at 3D PDF

Consortium http://www.3dpdfconsortium.org/pdf-standards-info.html.

Thanks

for reading! I would be happy read your comments.

Labels:

3D PDF,

Data Visualization,

Legacy Data,

PLM,

Records Management,

Support,

Visualization

Friday, October 14, 2011

What Google+ failure can teach about PLM implementation and User Adoption?

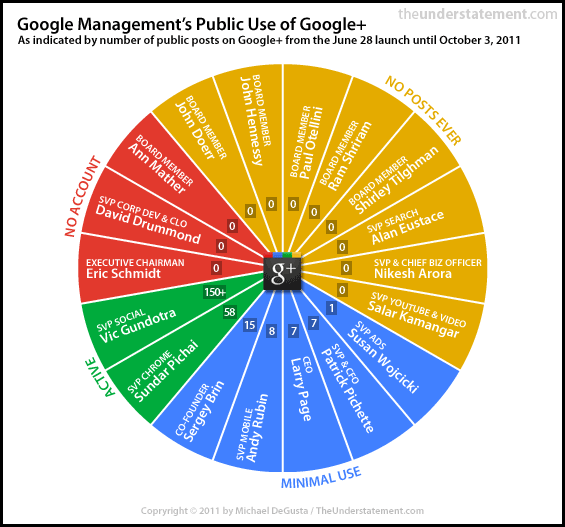

A few days back, Google engineer Steve Yegge

wrote a classic tirade about Google's inept handling of the Google+ platform.

(You can read it all here). Google+ was supposed to be a Facebook killer, but slowly it is turning to be

another Google Wave/Buzz.

One of the most interesting things pointed out in the blogpost was “The Golden

Rule of platforms is that you Eat Your Own Dogfood”.

The fact that Google doesn’t even eat its own dog food is very evident in this

post from a few days back.

A few days back, Google engineer Steve Yegge

wrote a classic tirade about Google's inept handling of the Google+ platform.

(You can read it all here). Google+ was supposed to be a Facebook killer, but slowly it is turning to be

another Google Wave/Buzz.

One of the most interesting things pointed out in the blogpost was “The Golden

Rule of platforms is that you Eat Your Own Dogfood”.

The fact that Google doesn’t even eat its own dog food is very evident in this

post from a few days back.  As I read this post, I realized how many times

we have implemented PLM at various sites and, what the end result has been - all

along we have known for a fact that the one of the key measure of a winning and

thriving PLM implementation was effective user adoption. And this not mere consultant

conjecture, this has been validated by research too - According to a

study

done by the Sand Hill Group and Neochange, the most critical factor (70%

listed as number 1) for software success and return-on-investment is effective

user adoption. Software functionality came in at 1% surprisingly, with

organization change at 16% and process alignment at 13%.

No wonder Google+ has been a nonstarter (Paul Tassi has even written “A Eulogy for Google Plus”)

As I read this post, I realized how many times

we have implemented PLM at various sites and, what the end result has been - all

along we have known for a fact that the one of the key measure of a winning and

thriving PLM implementation was effective user adoption. And this not mere consultant

conjecture, this has been validated by research too - According to a

study

done by the Sand Hill Group and Neochange, the most critical factor (70%

listed as number 1) for software success and return-on-investment is effective

user adoption. Software functionality came in at 1% surprisingly, with

organization change at 16% and process alignment at 13%.

No wonder Google+ has been a nonstarter (Paul Tassi has even written “A Eulogy for Google Plus”)

So what can we learn about

Google+ hopeless case and how it relates to a successful PLM implementation

from a user adoption standpoint? Several I would say:

1. Not Enough Power Users

(or Management Support or Practice what you preach): Google's Schmidt finally took

to Google+ only a couple of days back.

Most members of the company's management team aren't still using Google+.

Likewise if your PLM implementation has to be successful the concerned top

level management has to use it. No point if the VP or Director of Engg/Rnd

still uses emails to approve designs or wants printed copies or whatever

completely bypassing the system.

2. Have Real Value for the End

User: If the current PLM system is just a replacement for the old one with lots

of cute UI’s and bells and whistle – quite likely the reaction is going to be

the same as was with the old one once the initial hype cycle dies down.

3. Launch when ready: Most

people would advocate implementing PLM in phases. Good point. But just because

you have to close out one phase to start another doesn’t mean you need to roll

out a half baked product/service to the user community.

4. Vendor Size Doesn’t

Matter: Even with an 800 pound gorilla’s backing, Buzz, Wave and now + failed.

Likewise even if the vendor is large or their PLM system caters to the biggest

of the big Fortune 500 companies, it’s not necessary that it will cater to all

your user needs. Give your users what they want to be successful in getting

their job done. Don’t focus almost exclusively on tiny little features that few

people will ever use.

5. Customize if needed: Oh yeah, that’s

a bad word – We don’t want to customize and keep on paying for the maintenance!

Right – But what is the point in using terminology or vendor mandated business

processes which the user community doesn’t understand? I still don’t get

circles, stream, hangouts or whatever.

6. Motivate People to Use it: People

simply didn’t move in droves from Facebook to Google+ as was expected. There

was no motivation to do so. FB was sufficient to satisfy the needs of most of

the users. Just because something is mandated by the organization doesn’t mean

that the users will use it or be happy to use it (sometimes you don’t have a

choice – like using LotusNotes or HP’s Quality Center for example!). Motivate

the end users to use the new PLM system – Have a plan much before go-live!

7. Integration: Well

Google+ has probably integration with lots of websites and stuff, but Facebook

is better! Host of games and apps and I can even sign into/comment on a bunch

of websites using my Facebook id. Similarly if the PLM system doesn’t have

integration to systems like corporate LDAP, or the SMTP server or inaccessible

externally users would have tough time getting on-boarded.

Probably I can go on and on but

I hope readers get the point! Don’t take user adoption unconscientiously – it’s

the key to a triumphant implementation. (I wouldn’t underestimate Google though

– Maybe this time they will get it right – eventually)

Labels:

Google+,

PLM,

PLM Implementation,

Social Media,

User Adoption.

Saturday, September 24, 2011

The under-appreciated role of PLM in implementing Document Creation Retention and Destruction (DCRD) policies

Have you heard about the famous (or infamous?) “Pitt’s Postulate”: “Whenever you think you’ve destroyed the last copy of any document, there’s always one more that exists, and it will surface at exactly the most inopportune time. The only exception, of course, is if you really need the document, at which point you’ll discover that you actually did destroy the very last copy.” – Quite true, isn’t it? Over the last few years businesses have come to appreciate that they need to better manage their documents and records to tackle a number of key issues including legislation's like SOX, risk of lawsuits, protection of intellectual property and identity theft. Most corporations have formalized Document Creation, Retention and Disposal (DCRD) policies, primarily outlining the length of time for which the organization will keep certain documents and records, either in hard copy or electronic form. These policies serve as guiding principles for employees, indicating which documents to discard and which to save while ensuring compliance with laws and hindering inadvertent or ingenuous destruction of records.

Have you heard about the famous (or infamous?) “Pitt’s Postulate”: “Whenever you think you’ve destroyed the last copy of any document, there’s always one more that exists, and it will surface at exactly the most inopportune time. The only exception, of course, is if you really need the document, at which point you’ll discover that you actually did destroy the very last copy.” – Quite true, isn’t it? Over the last few years businesses have come to appreciate that they need to better manage their documents and records to tackle a number of key issues including legislation's like SOX, risk of lawsuits, protection of intellectual property and identity theft. Most corporations have formalized Document Creation, Retention and Disposal (DCRD) policies, primarily outlining the length of time for which the organization will keep certain documents and records, either in hard copy or electronic form. These policies serve as guiding principles for employees, indicating which documents to discard and which to save while ensuring compliance with laws and hindering inadvertent or ingenuous destruction of records.Numerous off-the-shelf solutions are available for such purposes (including SharePoint which impelled me to write this article) but if a company has already implemented a commercial PLM system then they in all probability do not need to go for another system to take care of DCRD policies. Record/Document classification, integrity, storage, access control, data retention, backup, data purging, comprehensive version and revision control, viewable file generation, auditing, search etc. are all effectively present in a enterprise PLM system.

What are the challenges before trying to get PLM in managing corporate records?

→ Assessment of different document type and their value needs to be determined first – Certain type of documents might not be suitable for storage in PLM like employee evaluations or expense reports etc when other systems are present to manage them.

→ Emails in particular – Time and again emails have been the center of attention in much litigation and unfortunately the retention/control/purge of emails is out of PLM’s scope.

→ Backups – Electronic data backup produce historical copies of documents/records which even though purged from the current system will be preserved in archives and are discoverable.

→ Emails in particular – Time and again emails have been the center of attention in much litigation and unfortunately the retention/control/purge of emails is out of PLM’s scope.

→ Backups – Electronic data backup produce historical copies of documents/records which even though purged from the current system will be preserved in archives and are discoverable.

My conclusion: PLM is a viable solution in conjunction with other systems to aid implementation of DCRD policies. If a PLM solution is present then a new Records Management solution doesn’t need to be implemented.

Saturday, September 10, 2011

Securing your PLM Infrastructure (before it’s too late!)

I read an interesting report at Symantec’s website - The

average organizational cost of a data breach [in 2010] increased to $7.2

million and cost companies an average of $214 per compromised record, markedly

higher when compared to $204 in 2009. The full report is here.

Also per the Second Annual Cost of Cyber Crime Study

I read an interesting report at Symantec’s website - The

average organizational cost of a data breach [in 2010] increased to $7.2

million and cost companies an average of $214 per compromised record, markedly

higher when compared to $204 in 2009. The full report is here.

Also per the Second Annual Cost of Cyber Crime Study

Cyber attacks have become common occurrences. The companies in our study experienced 72 successful attacks per week and more than one successful attack per company per week. This represents an increase of 44 percent from last year’s successful attack experience.Pretty frightening huh! I am not sure it would be possible to break up such estimates into a granular level, but data loss from a PLM system would be also very expensive. And that needs to be seriously looked into. With this mission I looked at various PLM vendors websites – all they claimed was that their system was “highly secure” – But how secure is the question? Is there an established criterion or matrices or has it been quantitatively corroborated? CIMData deals with this topic in their white paper “TenQuestions to Ask PLM Solution Suppliers - What You Need to Know to Make anInformed Decision” though very briefly.

The risks are not only external but also present due to the fact that today users work from everywhere and not only from their office and even iPad apps are being released by several vendors. Other requirements like ITAR, export control, and other security protocols make it more imminent to secure your PLM environment. I believe during the PLM evaluation phase itself security mechanisms need to be evaluated and security should not be added as an afterthought.

Some of the security measures that come to mind (and nowhere

are these comprehensive):

→

Application Layer Security

o

Application Security – Including On-site and

off-site tape storage, OS hardening, Virus protection on all servers, etc.

o

User Authentication - Access Control and Data

classification model. Strike the right balance between sharing information and

securing it. See Ford’s slides on Product Data Security and Access Management.

→

Data Management Security

o

Data Encryption – 128-bit Secure Sockets Layer

(SSL) data encryption, etc.

o

Database Security – minimal open ports, no

scott/tiger or Default Password’s (I have seen

this a lot!), no master passwords to control access to all systems, No text (property)

file passwords!

o

Lock down on file vaulting servers(s)

→

Systems Security

o

Internal and Operating Systems Security –

Firewalls, network address translation, port redirection, IP masquerading,

non-routable IP addressing schemes, DMZ, Intrusion detection systems, etc.

o

PerimeterDefense including video surveillance

→

Data

Center Security

o

Physical

Security of server farms including biometric authentication for access. (Though one of my customers had an enterprise down scenario when rats gnawed down some of their fiber optic cables)

o

Reliability

and Backup –Hardware: UPS battery systems, diesel generators, and HVAC systems

– (I saw this first hand when a few years back a snow storm hit a customer site

in New England area and power lines were down, they didn’t have diesel

generators and UPS battery lasted only for an hour or so causing servers to

crash). Disaster recovery sites, Backup tapes also are important.

o

Reliability

and Backup –Hardware: UPS battery systems, diesel generators, and HVAC systems

– (I saw this first hand when a few years back a snow storm hit a customer site

in New England area and power lines were down, they didn’t have diesel

generators and UPS battery lasted only for an hour or so causing servers to

crash). Disaster recovery sites, Backup tapes also are important.

o

Water Suppression,

Fire protection facility in server room.

o

Social

Engineering – Do not underestimate the human aspect of security. Ignorant or discontented

employees can cause more harm than you can imagine. Former computer hacker Kevin

D. Mitnick has a good book on this topic: “The Human Element of Security”

Audits and Standards

Facilities can be designed to withstand extreme elements

that comply with ISO/IEC 27001 standards.

A SAS 70 Type II or SSAE 16 or ISAE 3402 audits can also be

done. A comprehensive security assessment and mitigation of risks related to

system would bring in peace of mind.

Conclusion

There is a Data Breach Risk Calculator available

which will estimate your risk exposure and can calculate amongst others the

cost of a data breach at your company.

Organizations should remember the costs involved

– What a mid tier firm might have the funds for will be appreciably different

from what a Fortune 100 firm would. They should pigeonhole the sets of security features

needed based on priority and significance and make practical decisions based on

their budget.

Friday, September 2, 2011

Creative problem solving using Visual Analytics in Product Development

Visual analytics is a new interdisciplinary science aimed at drawing inference and conclusions from data. In contrast to standard machine learning or statistics, visual analytics emphasizes information visualization, interactivity, and analytic reasoning. [http://smlv.cc.gatech.edu/2010/03/17/what-is-visual-analytics/]. It is an outgrowth of the field’s information visualization and scientific visualization, which focuses on analytical reasoning facilitated by interactive visual interfaces. [http://en.wikipedia.org/wiki/Visual_analytics]

If you really want to go into the depths of VA then you can attend a few web lectures from Georgia Tech here

A few years back digg.com had these great visualizations – stack, swarm and big spy; though they seem to be out of service now. (see Where Have Digg Labs Gone?)

A related disciple is text analytics. The term text analytics describes a set of linguistic, statistical, and machine learning techniques that model and structure the information content of textual sources for business intelligence, exploratory data analysis, research, or investigation. [http://en.wikipedia.org/wiki/Text_analytics]

A tag or word cloud is related to text analytics. We all have seen these tag clouds over the past couple of years. Tag clouds are an informative image that communicates much in a single glance. Word clouds are easy to read, analyze and compare, serve a variety of useful purposes including visual analysis of qualitative data. For example using FDA Medical Devices CFR - Code of Federal Regulations Title 21 and TagCrowd I created this visualization (clearly showing that the major emphasis of this regulation is on manufacturers.)

A tag or word cloud is related to text analytics. We all have seen these tag clouds over the past couple of years. Tag clouds are an informative image that communicates much in a single glance. Word clouds are easy to read, analyze and compare, serve a variety of useful purposes including visual analysis of qualitative data. For example using FDA Medical Devices CFR - Code of Federal Regulations Title 21 and TagCrowd I created this visualization (clearly showing that the major emphasis of this regulation is on manufacturers.)

Coming to the PLM domain, if we can process product data in such a method then we can arrive at a number of interesting observation very easily. For example to show which product has how many change requests? Or which product uses the least parts from a standard library. It can be easily done and if there is an enormous amount of data in an organization such visualizations can offer great information to executives very intuitively.

This sort of visualization when brought into an enterprise can easily put in the picture about a multitude of different things, like for example; a change in a standard part is going to affect how many products down the line, etc. I believe Visual analytics will lead to creative problem solving and faster solutions to problems will drive higher product profitability.

Labels:

BI,

Data Visualization,

Infographics,

Innovation,

PLM

Thursday, August 18, 2011

Data Visualization/Infographics in PLM – Will it help make better decisions?

As PLM implementations and usage have matured over time, from being a simple repository of CAD data to a single source of truth, the data locked in these systems have also increased exponentially. This data usually exhibits the key characteristics of good data – being well controlled, accurate, organized, relevant, reliable, and valid. This treasure trove can be harnessed to yield knowledge (which is a series of facts) and intelligence (the ability to think and reason and using and processing the knowledge) and to do that it needs to be properly understood. However till now in most cases such data have been presented only in the form of tabular search results with very little emphasis on mechanisms of illustrating the data in a form which enables a mental picture of what is being revealed.

“The adage "A picture is worth a thousand words" refers to the idea that a complex idea can be conveyed with just a single still image. It also aptly characterizes one of the main goals of visualization, namely making it possible to absorb large amounts of data quickly.” [http://en.wikipedia.org/wiki/A_picture_is_worth_a_thousand_words]

Most of the Inforgraphics I have seen till date seems to be one off creations of artists – Can an automated, scalable, efficient technology deliver infographics that is quickly refreshed with current data? As a matter of fact can we do multidimensional analysis of volumes of product data to get information about the business in a more intuitive way?

“The point is that the data [is] good but looking at it and trying to analyze it without an appropriate visual representation will not be helpful in drawing [any types of] conclusions or noticing any patterns. “ [http://veronicatsvetkov.com/2011/04/12/ted-talk-eric-brlow-data-visualization-tableau-public-software/]

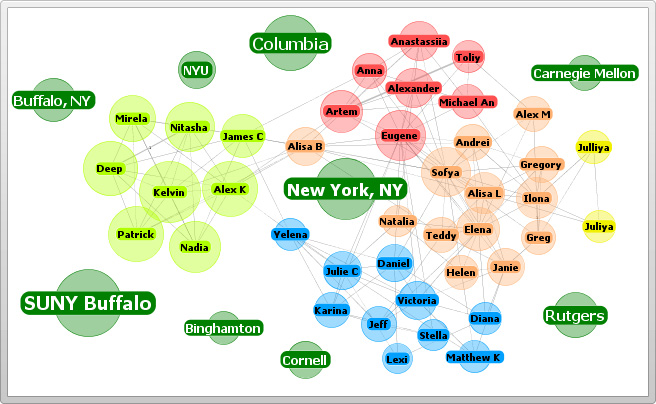

Infographics Example 1

I believe Infographics can help here. “Information graphics or infographics are graphic visual representations of information, data or knowledge. These graphics present complex information quickly and clearly, such as in signs, maps, journalism, technical writing, and education. With an information graphic, computer scientists, mathematicians, and statisticians develop and communicate concepts using a single symbol to process information”. [http://en.wikipedia.org/wiki/Information_graphics]

Infographics Example 2

“The adage "A picture is worth a thousand words" refers to the idea that a complex idea can be conveyed with just a single still image. It also aptly characterizes one of the main goals of visualization, namely making it possible to absorb large amounts of data quickly.” [http://en.wikipedia.org/wiki/A_picture_is_worth_a_thousand_words]

Infographics Example 3

Identifying solutions to problems becomes easier if complex data can be easily refined. See ecologist Eric Berlow illustrating the tips and tricks for breaking down big issues, he distills an overwhelming infographic on U.S. strategy in Afghanistan to a few elementary points.

Most of the Inforgraphics I have seen till date seems to be one off creations of artists – Can an automated, scalable, efficient technology deliver infographics that is quickly refreshed with current data? As a matter of fact can we do multidimensional analysis of volumes of product data to get information about the business in a more intuitive way?

Labels:

BI,

Data Visualization,

Infographics,

PLM

Monday, April 4, 2011

QR Code and PLM

Yoann some time back wrote an exciting article on Integrating QR-code tag in User form in Aras Innovator (http://bit.ly/dGW2gx). This is a very interesting union! I am surprised to see that not many PLM vendors have QR code generation facilities. For starters QR Code has the capacity to encode 7,089 numeric characters, 4,296 Alphanumeric characters or 2,953 bytes of binary data (http://en.wikipedia.org/wiki/QR_code).

QR Code was created by Toyota subsidiary Denso-Wave in 1994. As noted in the Denso-Wave’s case studies, QR code is being used in a variety of industries including Order/Product Scanning System for Automotive Parts, Process Control System for Electronic Circuit Boards, Logistics Control System for Food Products, Shipping Control System for Garment Products, etc. These codes contain varied data including product code, expiration date, manufacturing history, shipping destination, color, size, customer data, shipper data, production line, serial number etc.

The potential for QR Codes is limitless. What’s most exciting is how they take what social media is doing well now, bringing people together with technology, and extending it to enhance the experience (http://bit.ly/i3hs2S). Some suggested uses for QR codes in the AEC (Architectural, Engineering and Construction) industry include using these codes to Link to Technical Information, Testimonials or case Studies and Customer Service (http://bit.ly/eKWU5e) Howcast in a recent blind pitch to Ikea, the company illustrated how video and QR codes could be used to create clear, overlaying instructions to guide consumers through the furniture assembly process. Such technology could be leveraged not only to improve consumer satisfaction, but could very well cut down on customer support costs for the company as well (http://on.mash.to/9FUyO5).

Another interesting article here http://bit.ly/hurw73 shows how QR Codes has been used to foil counterfeiting, for example the counterfeiting of postage stamps. Many countries of Europe as well as Canada and the United States have implemented this scheme, although details vary from one country to the next.

There has been some discussion on identification of drawing using embedded QR codes (http://bit.ly/cyGup4 and http://bit.ly/cyNVe4) but there hasn’t been anything spectacular. QR Code generation is easy with number of sites allowing you to generate simple QR code for free including Google. (Go to http://goo.gl/ and enter the URL of the site which you want your QR code to be generated. Once you have shortened URL, put it in the URL bar and add .qr to it. Click enter and the QR would automatically created). Hopefully PLM vendors will wake up to this reality and provide options for generating such code in their solutions.

The potential for QR Codes is limitless. What’s most exciting is how they take what social media is doing well now, bringing people together with technology, and extending it to enhance the experience (http://bit.ly/i3hs2S). Some suggested uses for QR codes in the AEC (Architectural, Engineering and Construction) industry include using these codes to Link to Technical Information, Testimonials or case Studies and Customer Service (http://bit.ly/eKWU5e) Howcast in a recent blind pitch to Ikea, the company illustrated how video and QR codes could be used to create clear, overlaying instructions to guide consumers through the furniture assembly process. Such technology could be leveraged not only to improve consumer satisfaction, but could very well cut down on customer support costs for the company as well (http://on.mash.to/9FUyO5).

Another interesting article here http://bit.ly/hurw73 shows how QR Codes has been used to foil counterfeiting, for example the counterfeiting of postage stamps. Many countries of Europe as well as Canada and the United States have implemented this scheme, although details vary from one country to the next.

There has been some discussion on identification of drawing using embedded QR codes (http://bit.ly/cyGup4 and http://bit.ly/cyNVe4) but there hasn’t been anything spectacular. QR Code generation is easy with number of sites allowing you to generate simple QR code for free including Google. (Go to http://goo.gl/ and enter the URL of the site which you want your QR code to be generated. Once you have shortened URL, put it in the URL bar and add .qr to it. Click enter and the QR would automatically created). Hopefully PLM vendors will wake up to this reality and provide options for generating such code in their solutions.

Subscribe to:

Posts (Atom)